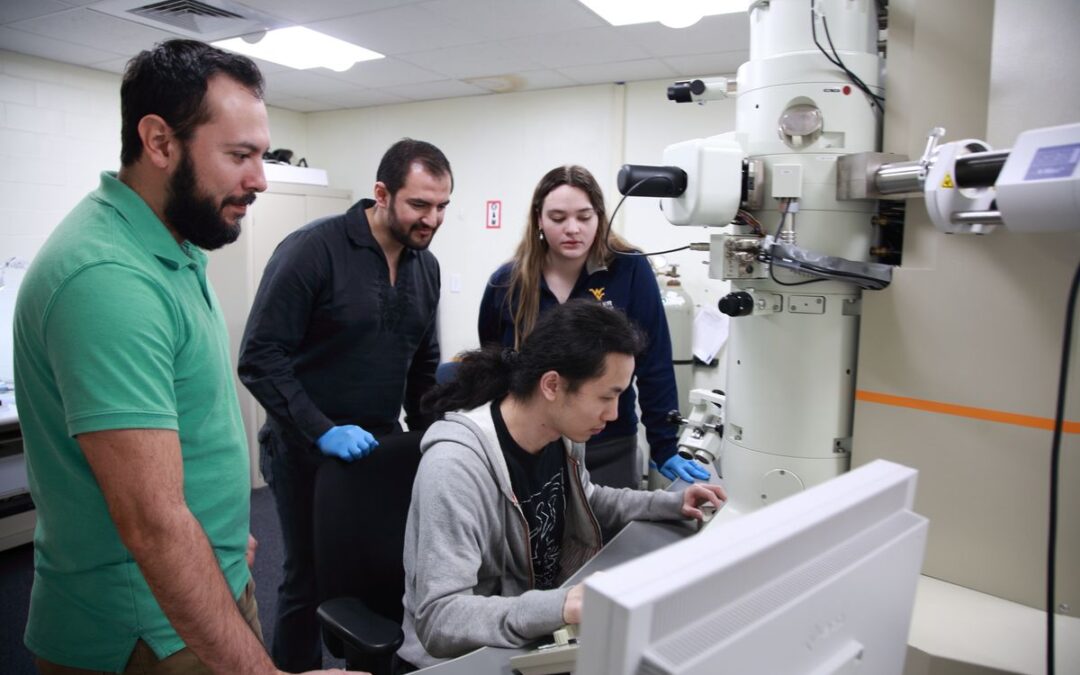

WVU researchers Sergio Andres Paredes Navia, Cesar Octavio Romo de la Cruz, Liang Liang and Ellena Gemmen use an electron microscope to study the nanostructure of a new oxide ceramic material with the potential to make thermoelectric generators efficient enough to capture a significant portion of the waste heat that industrial systems like power plants emit.

Article Source: WVU Today (West Virginia University)

Researchers at West Virginia University have engineered a material with the potential to dramatically cut the amount of heat power plants release into the atmosphere.

A team led by Xueyan Song, professor and George B. Berry Chair of Engineering at the Benjamin M. Statler College of Engineering and Mineral Resources, has created an oxide ceramic material that solves a longstanding efficiency problem plaguing thermoelectric generators. Those devices can generate electricity from heat, including power plant heat emissions, which contribute to global warming.

The breakthrough oxide ceramic Song’s team produced “achieved a record-high performance that had been deemed impossible,” she said. “We demonstrated the best thermoelectric oxide ceramics reported in the field worldwide over the past 20 years, and the results open up new research directions that could further increase performance.”

Cesar Octavio Romo de la Cruz, Yun Chen, Liang Liang and Sergio A. Paredes Navia contributed to the study, supported by $639,784 in National Science Foundation funding. The findings appear in Renewable and Sustainable Energy Reviews.

Oxide ceramics are from the same family as materials like pottery, porcelain, clay bricks, cement and silicon, but contain various metallic elements. They’re hard, resistant to heat and corrosion, and well-suited for high-temperature applications in air. They can serve as the material for thermoelectric generator components.

However, oxide ceramics have “polycrystalline” structures composed of multiple connected crystals. Engineers run into trouble with large-scale thermoelectric applications for those materials since the “grain boundaries,” the places where those crystals meet, block the current and electron flow that powers thermoelectric generators.

Song’s team converted that stumbling block into a stepping stone.

“We intentionally added ‘dopants,’ or metal ions, into the polycrystal ceramics, driving special kinds of dopants to segregate to the grain boundaries,” said postdoctoral researcher Romo de la Cruz. “That’s how we turned the unavoidable and detrimental grain boundaries into electricity-conducting pathways, significantly improving thermoelectric performance.”

The research responds to the growing problem of waste heat, a contributor to climate change and byproduct of most operations that convert fuel into power. When lightbulbs get hot to the touch, they’re giving off waste heat: inefficient extra energy that doesn’t contribute to their primary job of producing light. Waste heat is released into the atmosphere by systems as diverse as power plants, home heating systems and automobiles, and there’s enough of it being emitted that the global market for systems that recover it is projected to exceed $70 billion by 2026.

“Heat is used to make almost everything from food to metals and electricity,” Romo de la Cruz explained. “But during those processes, around 60% of the energy produced is unproductively released to the environment in the form of heat. Waste heat recovery will play an increasingly key role in balancing growing demand for electricity against the carbon footprint of industrial processes. Thermoelectric oxide ceramics like ours come into play by substantially improving the ability of thermoelectric generators to convert waste heat into electricity.”

Thermoelectric generators are a promising technology for waste heat recovery in part because they are simple to operate and maintain. A powerful thermoelectric generator could capture a significant portion of a power plant’s waste heat.

But “for the majority of applications, thermoelectric technology is too inefficient to be economical,” Song said. “Thermoelectric’s lack of effectiveness in converting energy severely hampers the development of thermoelectric devices, even though they are desperately needed.”

Her lab solved that problem using nanostructure engineering — manipulating the ceramic’s crystal structure on an atomic scale that can only be seen using an electron microscope — to create a dense, textured polycrystalline material that outperformed the single-crystal materials that are currently standard.

Although tuning the performance of various materials for thermoelectrics has stimulated intense theoretical and experimental work for decades, Song believes that for bulk oxide ceramics, her lab is the first to demonstrate a significant increase in the efficiency of energy generation from heat through the nano- and atomic-scale engineering of grain boundaries between crystals.

“This work is at the cusp for large-scale, high-temperature waste heat recovery,” she said. “It leads toward a new era for oxide ceramics and aligns with the U.S. Department of Energy’s Industrial Heat Shot initiative to develop cost-competitive industrial heat decarbonization technologies with at least 85% lower greenhouse gas emissions by 2035. Our findings could facilitate and accelerate materials design that is magnitudes higher than the current state of the art.”